Key Takeaways (or TL;DR)

- AI is no longer an optional upgrade; it has become essential for businesses aiming to optimize inventory processes and improve operational efficiency.

- AI-driven insights help businesses streamline operations by predicting demand, preventing stockouts, and improving overall accuracy.

- Successfully implementing an AI-based inventory management system significantly improves efficiency, accuracy, and decision-making processes.

- Integrating AI into inventory management offers compelling benefits; however, it also poses challenges, including data security and resistance to change.

- AI-driven inventory management promises to streamline processes and propel businesses towards a more efficient & competitive future through advancement in automation and predictive analytics.

- Collaborating with the right tech partner or adopting AI-powered inventory management solutions ensures continuous improvement and long-term scalability.

- Key Takeaways (or TL;DR)

- What is AI in Inventory Management? Understanding Its Impacts in Enhancing Inventory Operations

- Explore the Compelling Benefits of AI for Inventory Management

- How to Implement AI in Inventory Management – A Step-by-Step Guide

- Top 8 Effective Use Cases of AI for Inventory Management

- Key Challenges & Solutions of Implementing Artificial Intelligence in Inventory Management

- What Does the Future Hold For AI Inventory Management? – Explore its Emerging Trends

- How Can Elluminati Help You with Building Your AI-Powered Inventory Management

- FAQs

In today’s fast-evolving market landscape, maintaining precise control over stock has become essential for operational efficiency and sustainable growth, and this is where AI in inventory management comes into play. It enables businesses to move beyond manual processes by adopting intelligent forecasting, automated tracking, and data-driven decision-making, thereby significantly enhancing their overall inventory operations.

Now, for businesses like yours eager to adopt AI inventory management, this comprehensive blog is the perfect destination. Here, we will walk through the transformative benefits of intelligent inventory management, explore its real-world applications, and more.

What is AI in Inventory Management? Understanding Its Impacts in Enhancing Inventory Operations

AI in inventory management refers to the use of advanced AI technologies, such as machine learning, predictive analytics, and automation, to manage stock more accurately and efficiently across supply chain operations.

Unlike traditional inventory management, which relies on manual inputs or periodic checks, AI evaluates real-time and historical data to help businesses maintain accurate inventory levels, reduce errors, and streamline decision-making.

The growing adoption of these technologies is reflected in market trends, as the AI in inventory management market size is projected to reach USD 27.23 Bn by 2029. This exponential growth reflects how businesses are increasingly leveraging AI to process vast amounts of data and generate accurate predictions, ultimately improving overall operational productivity.

AI enhances inventory operations through automated tracking, intelligent alerts, and predictive insights. These capabilities allow businesses to maintain optimal stock levels and replenish items in a timely manner with minimal human intervention.

In addition, AI integration with IoT enables real-time monitoring of inventory conditions, like temperature and humidity, which is crucial for industries such as food. This automation boosts operational efficiency, ensures timely product availability, and improves order fulfillment and lead times.

Explore the Compelling Benefits of AI for Inventory Management

Artificial intelligence is transforming inventory management by automating workflows, improving accuracy, and enabling data-driven decisions, helping businesses reduce operational risks and better manage supply chain complexity.

Smarter Warehouse Operations

Managing a warehouse has never been simple, as products move constantly, customer expectations rise, and even small delays can impact the overall supply chain operations. That’s exactly where AI-driven inventory management comes into play.

By combining intelligent automation, robotics, and real-time analytics, AI enables businesses to achieve precise demand forecasting, minimize excess stock, and enhance safety by monitoring hazards and alerting employees.

Dynamic Pricing Strategies

AI-powered dynamic pricing is considered a tactical tool because it enables businesses to adjust prices in real time based on factors such as changing market trends, seasonal variations, actual market demand, and customer behavior.

Through this, businesses can prevent over- or underpricing to maximize revenue and gain a competitive advantage.

Supplier Relationship Management

Strong supplier relationships are critical to maintaining smooth inventory operations. Shipment delays can result in backorders, customer dissatisfaction, and lost revenue, making effective supplier management essential for business continuity.

With AI-powered supplier relationship management systems, you can analyze supplier performance data, delivery patterns, and market conditions to provide actionable insights. This helps you improve delivery accuracy, while also creating a more robust supplier networks that support maintaining a consistent inventory availability

Real-Time Inventory Management

Keeping accurate inventory across multiple locations is one of the biggest operational challenges that every business faces. However, real-time inventory management powered by AI enables continuous, automated monitoring of stock levels across all locations, using various sensors, IoT (Internet of Things) devices, and advanced algorithms to track products as they move through the supply chain.

By integrating smart inventory management tools, businesses can improve accuracy, update inventory faster, and gain better visibility, helping them optimize stock levels in real time and increase customer satisfaction by ensuring product availability as demand rises.

AI-Enabled Demand Forecasting

Predictive analytics plays a game-changing role across the entire inventory management process. By analyzing historical data, market trends, and external factors such as seasonality and economic shifts, this AI-driven tool helps businesses predict future demand.

These insights enable businesses to align inventory levels with actual demand, reducing waste, improving customer satisfaction, and optimizing resource planning across the supply chain.

Cost Reduction & Optimization of Storage

One compelling reason businesses are adopting artificial intelligence in inventory management is the potential for significant cost reductions and effective storage optimization.

AI-driven inventory optimization helps reduce holding costs by improving stock optimization and providing real-time insights into inventory movement. This ensures businesses stock the right quantity of products and allocate the remaining funds to more strategic inventory management that drives your business towards sustainable growth.

Increase Accuracy & Efficiency in Stock

Another significant benefit of AI in inventory management is the ability to enhance accuracy and efficiency in the stock. AI’s advanced algorithms analyze real-time data, such as

- Sales

- Returns, and

- Inventory levels, to adjust stock allocation.

Additionally, businesses can leverage technologies such as computer vision and AI-powered barcode scanning to streamline their stocktaking processes. This not only saves valuable time but also boosts accuracy with minimal human effort.

Experience up to 45% Automation in Your Inventory Operations by Adopting an Inventory Management System from Elluminati

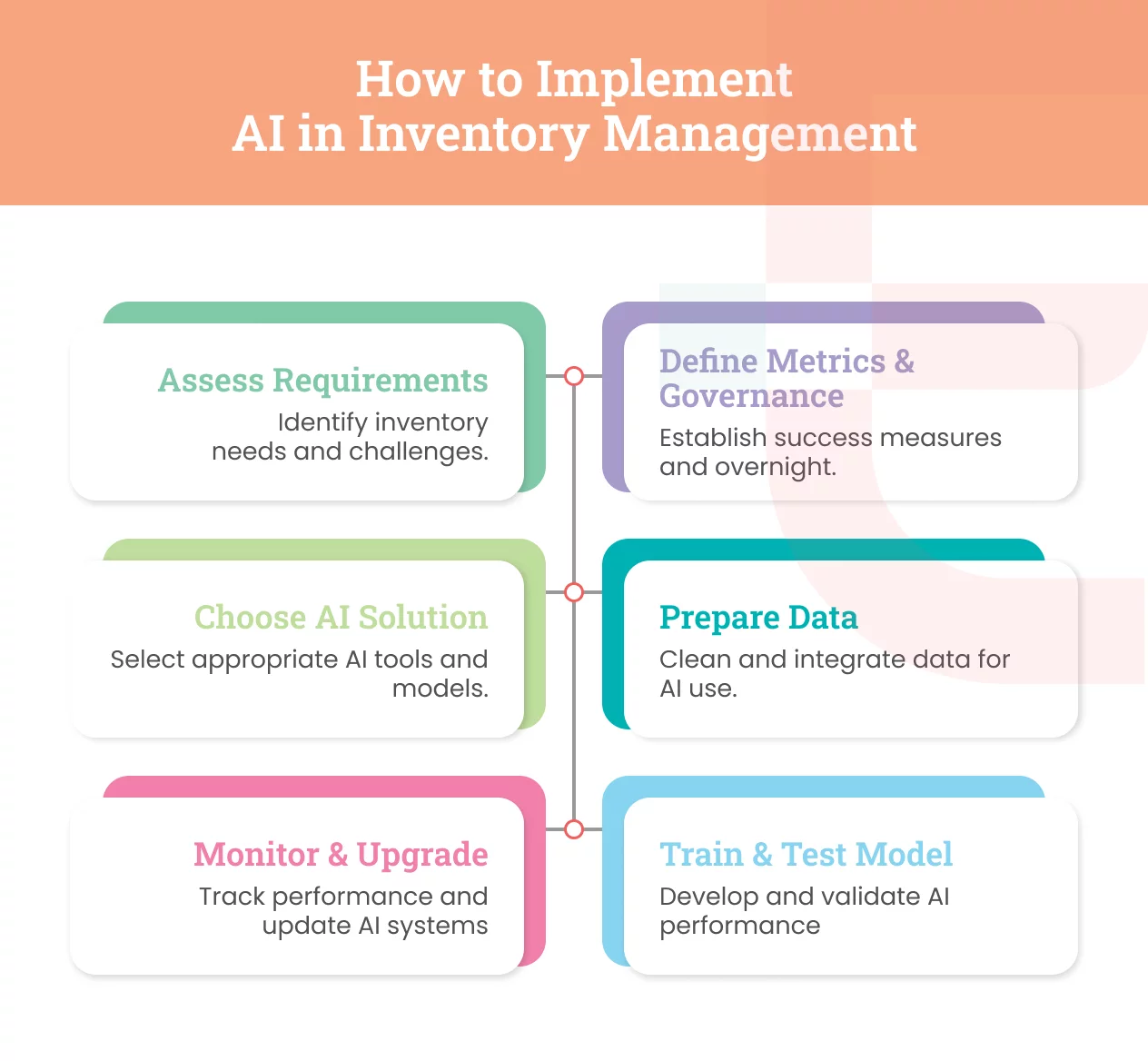

How to Implement AI in Inventory Management – A Step-by-Step Guide

Assess Your Inventory Management Requirements

The first and foremost step in implementing artificial intelligence in inventory management is understanding and assessing your current inventory management processes. Determining the key pain points of your business that you want to resolve with AI, such as:

- Stockouts, or overstocking

- Inaccurate forecasting

- Delays in reordering, etc.

These internal assessments and employee feedback will help you determine which areas could benefit more from AI-driven systems.

Define Success Metrics & Project Governance

After successfully assessing key requirements, you need to prepare clear success metrics for your project. This includes reducing stockouts by a specified percentage, improving forecast accuracy, or optimizing reorder points.

Establishing a project governance structure to assign responsibilities, set timelines, and ensure accountability across teams during the AI implementation process.

Choose the Right AI Solution

Selecting appropriate AI technology based on your project requirements is very important. For instance,

- Opt for machine learning models for demand forecasting

- Predictive analytics for replenishment optimizations, and

- Natural language processing (NLP) for analyzing supplier email or customer feedback.

Every technology has its own use cases, so choose the technology that matches your final objective. Also, it is essential to determine whether you need a fully integrated AI system or a modular solution that integrates with your existing inventory system.

Data Requirements & Preparation

AI relies heavily on accurate and well-structured data. Therefore, clean and preprocess the data to remove duplicates, fill missing volumes, and standardize formats.

Also, utilizing AI-powered data visualization will help you provide businesses with deep insights into the latest trends, anomalies, and patterns that may influence inventory decisions.

Model Training & Testing

Develop AI models tailored to your inventory needs. For example, train & validate ML models for demand forecasting, stockout prediction, and supplier performance analysis, and refine the models iteratively to ensure reliability.

Testing ensures that AI predictions are accurate and actionable before full-scale deployment.

Continuous Performance Monitoring & Upgrade

AI models require ongoing monitoring to remain effective. Therefore, tracking its performance metrics, such as forecast accuracy, stock levels, and fulfillment rates, is essential.

Also, update models as new data becomes available and refine the algorithms to adapt to changing market conditions. As we all know, continuous improvement ensures that your AI-driven inventory management systems evolve with your business needs.

Top 8 Effective Use Cases of AI for Inventory Management

Demand Forecasting

Modern businesses operate in highly unpredictable markets where customer demand fluctuates rapidly, right? Relying solely on past data is no longer sufficient, as it leads to stock imbalance, missed sales, and supply chain inefficiency. This is where predictive analytics comes into play.

By analyzing historical data, rapidly changing market trends, and evolving customer preferences, this system significantly reduces stockout risk. It enables businesses to achieve faster, more accurate order fulfillment across global operations.

One key example of this is Amazon. This worldwide popular brand uses AI-powered demand forecasting to analyze past data, customer purchasing trends, and other factors, such as weather, to minimize stockouts and ensure on-time product delivery.

Why Business Needs It:

- It helps align procurements and productions with real-time demand.

- Enhances profitability by reducing waste and optimizing inventory levels.

Real-time Inventory Tracking

In multi-location businesses, delayed or inaccurate stock visibility can cause operational disruptions, customer dissatisfaction, and unnecessary holding costs. Therefore, businesses that use RFID (Radio Frequency Identification) tags and integrate AI with other systems, such as Point-of-Sale (POS) terminals, can update inventory records instantly as products are sold or returned.

This helps businesses eliminate manual errors and provides teams with precise data for informed decision-making. One good-to-go example of this use case is Walmart. It has deployed inventory-tracking sensors in collaboration with Wiliot to improve supply chain efficiency and inventory accuracy, while also monitoring stock levels and locations in real time.

Why Business Needs It:

- It enables businesses to track stock with minimal manual intervention precisely.

- Also, it supports quicker replenishments and improves supply accuracy.

Smart Replenishment (Reordering) Systems

Determining how much inventory to order is the key thing every business must learn. After all, effective reordering requires a thorough understanding not only of the inventory currently available but also of its potential expiration or obsolescence dates, storage locations, demand, supplier fulfillment times for new orders, and more.

With AI, reorder points and order quantities are dynamically adjusted using demand forecasts and predefined inventory policies. This streamlines the ordering process, ensuring timely inventory replenishment to efficiently meet customer demand.

A key example of this application is Zara. This brand has adopted a replenishment system for its operations, automatically refilling the top-selling items in its flagship stores within hours of a sale.

Why Business Needs It:

- It helps businesses enhance their operational efficiency with automated decision-making.

- Also, it prevents them from losing sales by ensuring a timely restocking.

Warehouse Robotics & AI

Warehouse environments face increasing pressure to process more orders in less time while maintaining accuracy & safety. Manual operations alone are not scalable and often lead to bottlenecks. So, businesses are adopting warehouse robotics to automate repetitive tasks and streamline workflows.

Robots equipped with AI and computer vision technology assist businesses in picking, sorting, transporting, and packaging goods. These systems analyze warehouse layouts, predict the fastest routes, and optimize movement patterns drastically to improve overall operations.

Amazon’s Kiva Robots is one of the best examples. Empowered by AWS robotics, the brand reduced order cycle times by 20% and tripled pick rates in high-volume fulfillment centers.

Why Business Needs It:

- It assists them in enhancing accuracy and speed in warehouse operations

- Scale fulfillment capacity without compromising quality

Anomaly Detection

Inventory issues, such as unexpected demand spikes, abnormal shrinkage, stock mismatches, or supplier delays, can severely impact profitability. AI-driven anomaly detection helps businesses identify these irregularities early, preventing problems from escalating.

Using AI algorithms such as machine learning, it continuously scans inventory data to detect patterns that deviate from expected norms. Whether it’s sudden drops in stock levels or irregular ordering spikes, AI flags the issues instantly for corrective actions.

Why Business Needs It:

- It helps them easily detect errors and risks early.

- Improves the reliability of inventory and supply chain data.

Supplier Management

Robust supplier relationships are crucial to maintaining a stable product flow and avoiding costly delays. With the help of AI data analytics tools, which enable intensive analysis of supplier performance metrics, these tools are efficient at assessing factors such as delivery times, quality, pricing, and more.

Leveraging AI-driven insights, businesses coordinate strategically with suppliers to ensure they have the right amount of inventory at the right time. Effective supplier management helps streamline the procurement process, reduce lead times, and prevent overstocks and stockouts, thereby improving business profitability.

Why Business Needs It:

- Enables data-driven supplier selection and negotiations.

- It helps businesses predict potential supply chain risks early.

Inventory Classification

For businesses, managing a diversified product portfolio can be difficult, especially when thousands or even millions of stock-keeping units (SKUs) are involved. This is where AI-powered inventory classification plays a significant role. It simplifies inventory segmentation by analyzing sales performance, profitability, demand patterns, and inventory turnover to effectively categorize items.

Moreover, AI-led classification, such as ABC analysis, helps businesses prioritize important SKUs, allocate storage efficiently, and plan replenishment strategies more strategically.

Why Business Needs It:

- Enhances inventory allocations and storage efficiency.

- It automates classifications with precision and consistency.

Dynamic Safety Stock Optimization

Conventional safety stock methods rely on static formulas that fail to adapt to dynamic market conditions. With unpredictable demand and omnichannel operations, businesses need smarter systems that adjust safety stock in real time. AI-enabled safety stock optimization helps balance service requirements with cost efficiency.

AI models continuously analyze demand variability, lead-time fluctuations, and service-level targets to determine the ideal safety stock for each SKU. This ensures businesses avoid stockouts while also keeping excess inventory to a minimum, leading to higher ROI.

Why Business Needs It:

- It prevents overselling and stockouts across channels.

- Adjusting safety stock dynamically based on market conditions.

Future-Proof Your Operations with an AI-Powered Inventory Management System by Partnering with Elluminati

Key Challenges & Solutions of Implementing Artificial Intelligence in Inventory Management

Implementing AI in inventory management offers transformative value to businesses, but they often encounter key challenges during adoption.

From integration challenges to data security threats, addressing these roadblocks is essential to unlocking the full potential of advanced AI solutions.

High Implementation Costs

One of the key challenges a business faces when implementing AI for inventory management is its high cost. This includes acquiring the necessary hardware & software, as well as training personnel to use and maintain the systems.

For small and medium-sized enterprises, the upfront cost of adopting AI solutions may be a barrier.

Solution:

Businesses can overcome this cost barrier by opting for scalable, cloud-based AI tools and implementing them gradually to generate ROI effectively.

- Adopt modular AI tools, such as TensorFlow, PyTorch, and Scikit-learn, to reduce upfront capital expenses.

- Begin with high-impact areas to build ROI that funds wider adoption.

Integration Complexity

Many businesses have already modernized their business by integrating AI-based inventory management software. However, some people still rely on outdated systems to operate and manage their inventories.

Therefore, when it comes to integrating AI into legacy systems, such as ERP or supply chain management systems, they tend to become increasingly complex and expensive, as mismatches in data, formats, and incompatible systems can disrupt overall operations.

Solution:

One of the most effective ways to overcome this challenge is to leverage APIs, middleware, and flexible AI platforms to integrate AI seamlessly without large-scale system replacements.

- Opt for the AI systems built for plug-and-play compatibility.

- Utilizing a middleware to connect legacy tools with a modern AI solution.

Resistance to Change

Even when entrepreneurs are ready to embrace AI, employees may feel uncertain or threatened by automation, often due to fears of job displacement or lack of understanding. This resistance can delay AI implementations and reduce the effectiveness of new technologies.

Solution:

The best way to remove this roadblock is for businesses to maintain clear communication and provide hands-on training to help employees understand AI as a support tool that enhances productivity, not as a replacement for their roles.

- Offering them continuous training and role-based learning programs.

- Demonstrates AI’s values through real use cases and pilot programs.

Over-Reliance on Automation

Every AI system requires constant monitoring and updating. If a business relies too heavily on an intelligent inventory management system, it can lead to reduced human oversight, resulting in many crucial mistakes going unnoticed due to a lack of manual intervention or timely checks.

Solution:

The most effective way to remove this roadblock is for businesses to adopt both AI and human roles equally. They should enhance decision-making and not replace it entirely with AI systems.

- Aligning AI insights with the human mindset in critical workflows helps avoid last-minute mistakes.

- Conducting regular audits and manual verification checks is mandatory.

Security & Compliance Concerns

We all know that to deliver results in real time, AI needs access to sensitive business data, including sales transactions, inventory levels, and crucial customer information. Lack of security here can lead to vulnerability against cyberattacks, resulting in data breaches and huge financial losses, while also affecting brands’ value and trust.

Solution:

Implementing robust cybersecurity protocols and complying with regulations ensures safe data handling and strengthens customer trust.

- Use encryption, role-based access controls, and secure API frameworks.

- Maintaining compliance with GDPR and industry-specific standards is a must.

What Does the Future Hold For AI Inventory Management? – Explore its Emerging Trends

The future of AI in inventory management is shifting towards highly autonomous, insights-driven, and interconnected systems. As businesses embrace emerging AI trends, the inventory functions will evolve from reactive decision-making to a proactive, predictive, and error-resistant model, unlocking greater speed, efficiency, and cost optimization across the supply chain.

Hyper-Accurate Demand Forecasting

AI-driven forecasting is entering a new era in which systems evaluate real-time sales data, economic indicators, local events, and behavioral data to deliver unmatched accuracy. This helps businesses prevent stockouts, minimize overstock, and maintain leaner, smarter inventory.

- It provides personalized micro-forecasting for individual SKUs and customer segments.

- Visually providing predictions about the future using human-augmented technologies, resulting in more accurate decisions.

- Adaptive learning models that constantly improve prediction accuracy.

Fully Autonomous Supply Chains

AI will soon orchestrate the entire supply chain process independently, from demand evaluation to order placement, supplier selection, and transportation route adjustments, without human intervention. This enables businesses to create a highly efficient and disruption-resistant operational flow.

- It automates integrations across legacy systems using intelligent tools.

- Predicts ordering aligned with real-time demand fluctuations.

- AI-powered self-learning logistic system for dynamic delivery and route optimization purposes.

Automate Operations

Warehouses will increasingly rely on computer vision and robotics to handle physical inventory counts, picking, and replenishment at speeds and levels of accuracy unattainable by humans. It will help businesses instantly capture and reconcile inventory data, ensuring real-time visibility across the supply chain, accelerating fulfillment, and reducing human error.

- Automated storage and retrieval systems with real-time optimization

- Smart defect detections using an advanced vision system

- Intelligent conveyor systems regulate continuous workflows.

Voice-Based Warehouse Operations

AI-powered voice assistants will transform warehouse workflows by enabling hands-free operations, faster task execution, and reduced administrative efforts. Workers will interact with systems via simple verbal commands to complete their work with minimal effort and high efficiency.

- Utilization of AI-powered chatbot solutions for prompt inventory checks & reporting

- Real-time assistance for handling operational executions.

- Voice-enabled picking, packing, cycle counting, and replenishment processes.

Augmented Reality + AI

By blending AI with virtual reality and augmented reality, businesses can visualize data, navigation paths, and workflows directly in their physical environments, reducing errors and speeding up operations. There is nothing wrong with saying that, together AR and AI will redefine warehouse productivity by providing instant, visual guidance that enhances accuracy and decision-making.

- AR-powered picking path for faster retrieval.

- AI-assisted training and onboarding through immersive AR tools.

- Real-time shelf scanning to detect misplaced or missing items.

How Can Elluminati Help You with Building Your AI-Powered Inventory Management

AI in inventory management is transforming how businesses maintain an optimal balance between stock levels and resource allocation. With the growing demand for agility and precision in today’s supply chain operations, businesses are increasingly turning to AI-powered solutions to revolutionize their inventory management processes, and this is where Elluminati comes into play.

As a leading AI development company, we have a team of AI professionals dedicated to helping you build a scalable platform that integrates seamlessly with your existing systems. From demand forecasting and real-time tracking to automated replenishment and predictive analytics, we deliver a power-pack of features that enhance operational efficiency and position your business for long-term success in today’s competitive market.

FAQs

AI in inventory management helps improve accuracy, optimize replenishment, and provide features such as real-time tracking. This minimizes stockouts and overstock, while helping businesses predict market demand, enabling them to make better decisions, increase productivity, and maintain ideal inventory levels.

The following are some of the benefits of AI in inventory management

- Efficient resource utilization

- Enhanced accuracy

- Better customer service

- Improved demand forecasting

- Real-time inventory management & tracking

The cost for building an AI-powered inventory management system typically ranges from $10,000 to $200,000. However, there are several factors, such as the complexity of projects and other customized needs, that may influence the final costing. To obtain a more accurate quotation, we recommend that you contact our sales executive team at sales@elluminatiinc.com.

AI improves demand forecasting by analyzing historical sales data, customer behavior, seasonal trends, and external factors such as weather and economic conditions. Machine learning algorithms use this data to predict future demand more accurately, allowing businesses to optimize stock levels and meet customer demand without overstocking.